Pilkington SaniTise™

Pilkington SaniTise™ is an online coated glass with a transparent photocatalytic coating that provides antimicrobial properties and activity against enveloped viruses when exposed to UV. The coating on glass retains its properties even when UV exposure ends, for up to 2 hours in tests, further reducing the risk of cross-infection.

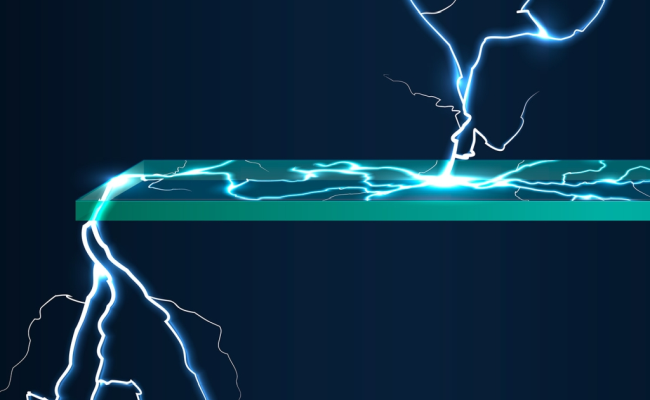

How it works

The glass uses a TiO2 based coating deposited directly onto the glass surface during its manufacturing process. When the Pilkington SaniTise™ coating is exposed to UV radiation from natural daylight or from UV disinfection devices it gets activated.

It then reacts with water vapour within the air, in a photocatalytic process that produces reactive oxygen species. These species provide a number of functions, including the ability to break down organic species, providing antimicrobial properties and activity against enveloped viruses on the glass surface.

When the coated glass surface is treated using a UV disinfection process, the effectiveness of disinfection is increased and in some cases doubled, compared to using uncoated glass.

Features & Benefits

- Pilkington SaniTise™ is a high quality glass with photocatalytic coating that can be used in a large variety of glazing applications.

- Pilkington SaniTise™ is highly resistant to corrosion, physical force and chemical damage.

- Pilkington SaniTise™ can be activated by sunlight or by artificial UV irradiation. It is rapidly activated by 254 nm light, the same used by UV disinfection systems.

- Pilkington SaniTise™ rapidly achieves its full activity upon exposure to UV light – only 5 to 10 minutes of UV exposure is needed.

- Pilkington SaniTise™ can double the effectiveness of UV disinfection processes.

- Once activated, Pilkington SaniTise™ retains photocatalytic activity for up to 2 hours, even in the dark.

- When activated, Pilkington SaniTise™ is also oleophobic (i.e. anti-fingerprint) and easier to clean than regular glass.

- The glass can be toughened, laminated, bent and processed into insulating glass units.

Applications

Exterior applications:

- glass facades,

- windows,

- doors,

- external partitions.

Interior applications:

- wall cladding,

- glass screens, barriers and partition walls,

- table tops, counter tops,

- splashbacks,

- furniture,

- freezers and refrigerators,

- cover glass for touch screens/displays.

Pilkington SaniTise™ Downloads

Pilkington Spectrum is a Windows-based glass performance model which enables you to quickly and efficiently calculate key properties of a wide range of single glazing and insulating glass units. Also available as an app for mobile devices, you can use Pilkington Spectrum to provide the following information:

- Light and solar properties (transmittance, reflectance, absorptance, g value, etc.).

- Centre pane Ug-value.

- Sound insulation values.

- Global Warming Potential (GWP), or carbon footprint.

- Ultra violet (uv) transmittance and colour rendering index (Ra).

- Other properties (e.g. pendulum body impact resistance, fire resistance, resistance to manual attack, etc.).

Please fill in the order sample form and we'll be in touch with you.

Order a sample

Please submit your details below and we'll be in touch shortly regarding one of our samples.