Glass Coatings

Surface Coatings

Because changing the basic composition in a glass tank to produce body coloured glass products is a lengthy and large scale operation, modified properties are produced from basic clear glass by surface coatings applied during manufacture on-line or subsequently off-line.

Off-line coatings

Off-line coatings are those which are applied to individual panes of glass once the glass has been manufactured and cut.

The application of coatings, by dipping panes into chemical solutions, drying and firing, or by evaporation of metals on to glass surfaces under conditions of vacuum, has been known for many years, but in the last decade application by magnetron sputtering of materials has come to the forefront.

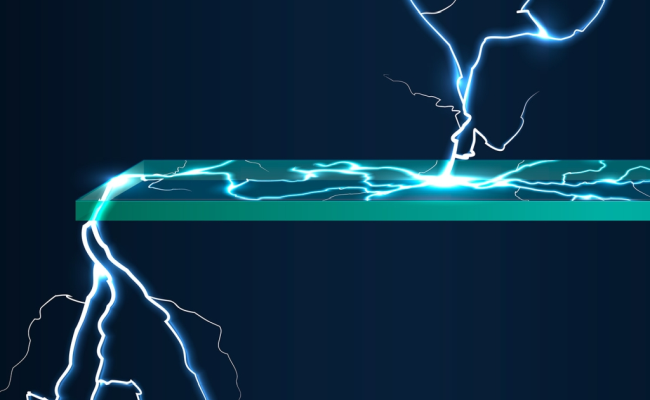

This process is capable of giving a wide range of coatings of different colours, reflectivities and thermal properties. In magnetron sputtering, the material to be sputtered is made the cathode of an electrical circuit at 500 volts.

Off-line coating concerns a process known as ‘Sputtering’ or ‘Physical Vapour Deposition’ (PVD), in which atoms of a target material are removed by the physical impact of argon ions and sputtered onto a glass substrate.

The process requires a high vacuum environment, roughly a billionth of normal atmospheric pressure, and thus it must be conducted in a pressure vessel - termed a coater.

This is to allow the ejected atoms to reach the glass substrate, without hitting an air molecule and being deflected away. The introduced argon gas forms a glow discharge plasma if a high negative voltage is applied to the target material, known as a cathode. Positive argon ions (having shed some of their electrons into a delocalised cloud in the plasma) are attracted to the negative cathode and impact it with considerable force. This results in atoms of the target material being ejected and building up on the substate below as they recondense forming a thin film. Magnets are also required to contain the plasma above the target material to help sustain the process.

The sputtering process allows fine control of film thickness, by varying the voltage on the target to change the rate of deposition.

Glass panes of up to 6000 mm x 3210 mm (jumbo size) can be coated, outputting approximately one pane a minute. A large variety of materials can be sputtered, both elemental metal, metal alloys or ceramics (a metal combined typically with either oxygen or nitrogen), provided they are at least somewhat conductive and not magnetic. Metals can also be sputtered in an atmosphere containing oxygen or nitrogen gas alongside the standard argon, resulting in the formation of a metal oxide or nitride on the glass substrate respectively.

Coating ‘stacks’ of multiple materials can be built up in one transit of the glass under sequential cathodes, the exact structure of the overall film determined by the function it is required to fulfil.

A variety of coated glass products are available to meet customer needs. Properties of the coated product, such as light transmission, g value, or colour, can be manipulated by adjusting the thickness of layers in the stack. Sputtered coated class is suitable for many applications, it can be used in insulating glass units or laminated glass. It can be provided as a toughenable, annealed or single stock coating as needed. Active research and development in this area is ongoing, to keep our sputtered coatings at the cutting edge of capability and to maintain our ability to fulfil future customer requirements.

On-line coatings

On-line modifications are made while the glass is hot and still in the annealing lehr. They may still be considered as basic products, and size and tolerance constraints are similar to those for clear float glass.

Surface coatings, either for solar control purposes or for reduced emissivity (a property to improve thermal insulation), are called pyrolitic coatings because they are generally applied to the hot glass during its passage through the annealing lehr. They involve the thermal decomposition of gases, liquids or powders sprayed on to the glass to form a metal oxide layer which fuses to the surface.

On-line coatings have advantages of hardness and durability over off-line coatings and are suitable for bending and toughening. They tend to be limited in variety of colour.

Dielectric coatings

The range of performances available from the use of metallic coatings is limited because of the thickness of coating which has to be applied. The use of dielectric coatings, which produce interference effects, allows higher light transmission with increased selectivity; the range of colours is also increased.

The maximum sizes of coated glass are dependent on the various facilities, and manufacturers' literature should be consulted.

It is not possible to toughen or bend most off-line coated glass; such work must be carried out before coating. It is possible to combine coatings in double glazed and laminated products.