Overview

Pilkington Optiwhite™ is a range of extra clear low-iron float glass products with very high solar transmittance, offering improved solar energy conversion and consistent performances. This range of low-iron glass products is suitable for use in thin film photovoltaics, crystalline silicon photovoltaics, concentrated solar power technology, solar thermal collectors and solar mirrors.

The Pilkington Optiwhite™ Range includes the standard and well established low-iron glass Pilkington Optiwhite™ and Pilkington Optiwhite™ S, which was developed specifically for the solar industry and offers even greater solar energy transmittance. Pilkington Microwhite™ is our Pilkington Optiwhite™ in its extremely thin version (glass thicknesses down to 1.0 mm).

With its very high solar energy transmittance, our low iron glass Pilkington Optiwhite™ is the ideal cover plate for a range of solar technologies, including Thin Film Photovoltaics, Concentrated Solar Power Technology and Solar Thermal Collectors. Pilkington Optiwhite™ can also be used as a cover plate for Crystalline Silicon Photovoltaics.

For more information on the Pilkington Optiwhite™ product range, please read our Pilkington Optiwhite™ brochures, or stay up-to-date with our latest solar glass news.

Benefits

Pilkington Optiwhite™ for solar applications offers following benefits:

- Very high light and solar heat transmittance

- Consistent lifetime performance following prolonged exposure to the sun (no solarisation)

- Available in annealed or tempered/toughened form for Pilkington Optiwhite™ and Pilkington Optiwhite™ S; available in annealed form only for Pilkington Microwhite™

Literature

Applications for Pilkington Optiwhite for Solar applications

Thin Film Photovoltaics

Characteristics of thin film photovoltaics

Thin film photovoltaic modules produce power at low cost per watt. They are ideal for large scale solar farms, as well as Building Integrated Photovoltaic applications (BIPV). They benefit from generating consistent power, not only at elevated temperatures, but also on cloudy, overcast days and at low sun angles.

For BIPV applications, thin film photovoltaics can offer excellent aesthetics. Thin film photovoltaic modules also benefit from a relatively small drop in power output under partial shadowing when compared with crystalline silicon photovoltaics. This gives thin film photovoltaic modules greater design flexibility when integrated into the building envelope.

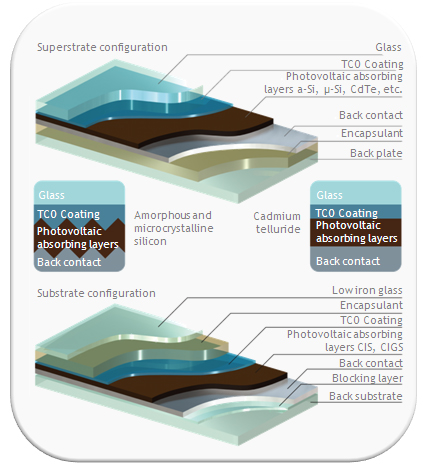

Thin film photovoltaics consist of a stack of extremely thin photosensitive layers sandwiched between a top Transparent Conductive Oxide (TCO) coating and a back contact. The photovoltaic layers are laminated between a TCO glass such as NSG TEC™, and a low cost backing material, such as standard or thermally strengthened Pilkington Optifloat™ Clear glass.

Thin film photovoltaic technologies

NSG TEC™ can be used with a number of thin film photovoltaic technologies, including amorphous silicon (a-Si), tandem (a-Si/μ-Si) – a combination of amorphous and microcrystalline silicon, cadmium telluride (CdTe), copper indium (gallium) diselenide (CIS, CIGS) and dye-sensitised solar cells (DSSC).

Pilkington Optiwhite™ range of products may also be used as a base for TCO deposition, or as a top cover plate for CIS and CIGS thin film photovoltaics. Pilkington Optiwhite™ is a range of ultra-clear float low iron glass, which maximises the solar energy transmittance and, therefore, the efficiency of the photovoltaic modules.

For more information on our solar glass product range, please read our solar glass literature or stay up-to-date with our latest solar glass news.

Crystalline Silicon Photovoltaics

Characteristics of crystalline silicon photovoltaics

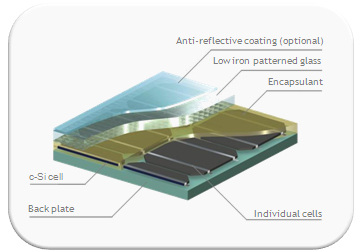

Crystalline silicon photovoltaics is the most widely used photovoltaic technology. Crystalline silicon photovoltaics are modules built using crystalline silicon solar cells (c-Si), developed from the microelectronics technology industry.

Crystalline silicon solar cells have high efficiency, making crystalline silicon photovoltaics an interesting technology where space is at a premium.

Crystalline silicon solar cells

There are two types of crystalline silicon solar cells used in crystalline silicon photovoltaics:

- Mono-crystalline silicon, produced by slicing wafers from a high-purity single crystal ingot

- Multi-crystalline silicon, made by sawing a cast block of silicon first into bars and then into wafers Mono-crystalline silicon solar cells have higher efficiencies than multi-crystalline silicon solar cells.

In crystalline silicon photovoltaics, solar cells are generally connected together and then laminated under toughened, high transmittance glass to produce reliable, weather resistant photovoltaic modules. The glass type normally used for this technology is rolled low iron glass such as Sunplus™Pilkington , often in toughened form, combined with an anti-reflective coating, to ensure that the maximum solar radiation reaches the crystalline silicon solar cells. It is also possible to use low iron float glass such as Pilkington Optiwhite™.

For more information on our solar glass product range, please read our solar glass literature or stay up-to-date with our latest solar glass news.

Concentrated Solar Power Technology

Characteristics of concentrated solar power technology

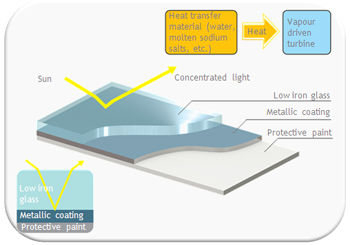

Concentrated solar power technology uses solar mirrors to concentrate sunlight.

The concentrated sunlight can either be directed onto a heat transfer material which generates electricity through a turbine, or onto a very high performance photovoltaic cell, which converts it into electricity. Concentrated solar power systems require direct sunlight and they generally follow the sun's path during the day through an axis tracking system. Typical examples are parabolic troughs and heliostat power towers.

The high performance solar mirrors are manufactured using metallic reflective coatings and weather protective paints deposited onto very high performance low iron float glass.

Since the sunlight has to travel through the low iron glass twice before reaching the heat transfer material, very high light transmittance, low absorptance glass such as Pilkington Optiwhite™ S, Pilkington Microwhite™ or low iron NSG TEC™ Sodium Block is required for this application.

For more information on our solar glass product range, please read our solar glass literature or stay up-to-date with our latest solar glass news.

Solar Thermal Collectors

Characteristics of solar thermal collectors

Solar water heating systems are generally composed of solar thermal collectors, a water storage tank or interconnecting pipes and a fluid system to move the heat from the collector to the tank. The sun's energy is used to heat water flowing through the interconnecting pipes. The water can be heated for a wide variety of uses, including domestic, commercial and industrial applications.

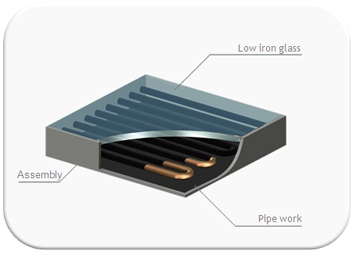

Flat-plate solar thermal collectors consist of an insulated box which contains a dark absorber plate under a glass cover that hermetically seals the system while maximizing the energy input. The glass cover plate will transmit the sunlight while protecting the system from harsh weather.

Toughened, high transmittance glass is required for this application; our Sunplus™Pilkington and Pilkington Optiwhite™ are ideal for such applications.

For more information on our solar glass product range, please read our solar glass literature or stay up-to-date with our latest solar glass news.

Pilkington Optiwhite™ Product Range

Our range of solar glass products includes the standard and well established low iron glass Pilkington

Optiwhite™, and Pilkington

Optiwhite™ S, which was developed specifically for the solar industry and offers even greater solar energy transmittance.

Pilkington

Microwhite™ is our Pilkington

Optiwhite™ in its extremely thin version (glass thicknesses down to 1.0 mm).

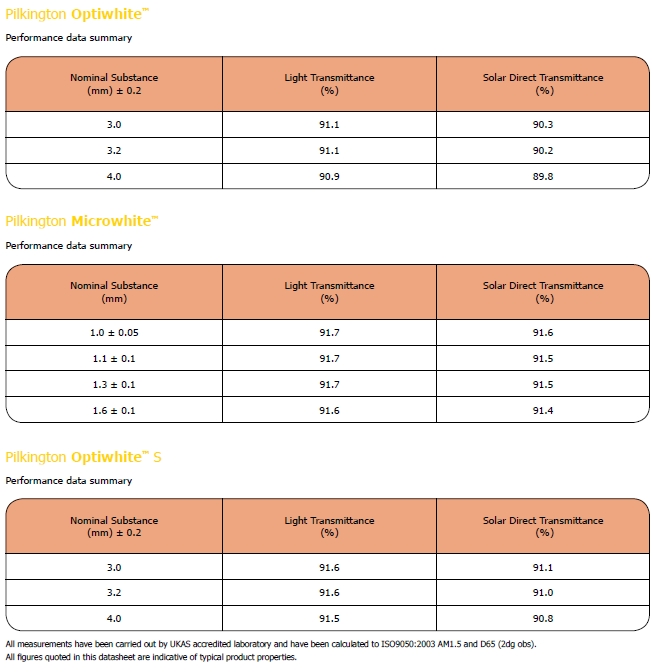

The properties of our Pilkington Optiwhite™ products are summarised in the table below: