NSG TEC™ for Solar Applications

Overview

NSG TEC™ is a group of products, including a comprehensive range of TCO glass (Transparent Conductive Oxide coated glass), optimised to suit a variety of thin film photovoltaics, with different haze and conductivity levels. All our NSG TEC™ products are manufactured using a patented chemical vapour deposition process to produce a durable, on-line pyrolytic coating that may be heat strengthened or fully tempered, providing complete flexibility for photovoltaic module production.

Each of our products within the NSG TEC™ Range is targeted at a particular thin film photovoltaic technology. For a-Si, a-Si/μ-Si, CdTe and DSSC technologies, properties such as light transmittance, Transparent Conductive Oxide conductivity (sheet resistance) and light trapping (haze) can be optimized to meet individual customer requirements.

Used in Thin Film Photovoltaics, NSG TEC™ is a range of coated glass designed and optimised for each of the main thin film photovoltaic technologies, including amorphous silicon (a-Si), tandem (a-Si/μ/Si), cadmium telluride (CdTe), copper indium (gallium) diselenide (CIS, CIGS) and dye-sensitised solar cells (DSSC).

Applications

Thin Film Photovoltaics

Thin film photovoltaic modules produce power at low cost per watt. They are ideal for large scale solar farms, as well as Building Integrated Photovoltaic applications (BIPV). They benefit from generating consistent power, not only at elevated temperatures, but also on cloudy, overcast days and at low sun angles.

For BIPV applications, thin film photovoltaics can offer excellent aesthetics. Thin film photovoltaic modules also benefit from a relatively small drop in power output under partial shadowing when compared with crystalline silicon photovoltaics. This gives thin film photovoltaic modules greater design flexibility when integrated into the building envelope.

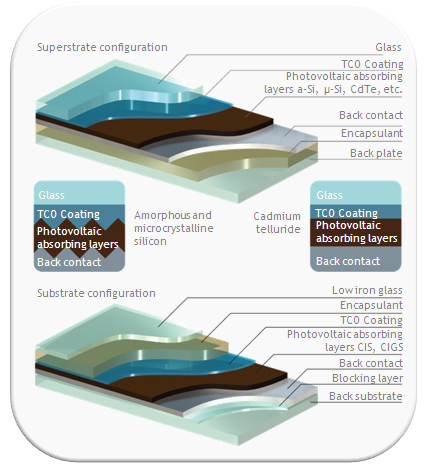

Thin film photovoltaics consist of a stack of extremely thin photosensitive layers sandwiched between a top Transparent Conductive Oxide (TCO) coating and a back contact. The photovoltaic layers are laminated between a TCO glass such as NSG TEC™, and a low cost backing material, such as standard or thermally strengthened Pilkington Optifloat™ Clear glass.

Thin film photovoltaic technologies

NSG TEC™ can be used with a number of thin film photovoltaic technologies, including amorphous silicon (a-Si), tandem (a-Si/μ-Si) – a combination of amorphous and microcrystalline silicon, cadmium telluride (CdTe), copper indium (gallium) diselenide (CIS, CIGS) and dye-sensitised solar cells (DSSC).

Pilkington Optiwhite™ range of products may also be used as a base for TCO deposition, or as a top cover plate for CIS and CIGS thin film photovoltaics. Pilkington Optiwhite™ is a range of ultra-clear float low iron glass, which maximises the solar energy transmittance and, therefore, the efficiency of the photovoltaic modules.

For more information on our solar glass product range, please read our solar glass literature or stay up-to-date with our latest solar glass news.

Benefits

NSG TEC™ for solar applications offers following benefits:

- High light transmittance, medium to high conductivity, low to high haze properties TCO glass to suit all thin film photovoltaics

- Coating properties are resistant to heat (i.e. unaffected by very high processing temperature)

- Can be fully tempered/toughened or heat strengthened without damage to the coating or drop in performance

- Durable on-line pyrolitic coating, making the product easy to transport, store, handle and process, reducing costs and lead Times,

- Available on standard clear or low-iron glass, depending on the coating type,

- NSG TEC™ C15 available with a choice of buffer layers (NSG TEC™ C15M and NSG TEC™ C15D),

- Sodium blocking performance,

- Virtually unlimited shelf-life,

- Available in a wide range of thicknesses, from 2.2 mm to 6 mm.

Brochures

NSG TEC™ Product Range

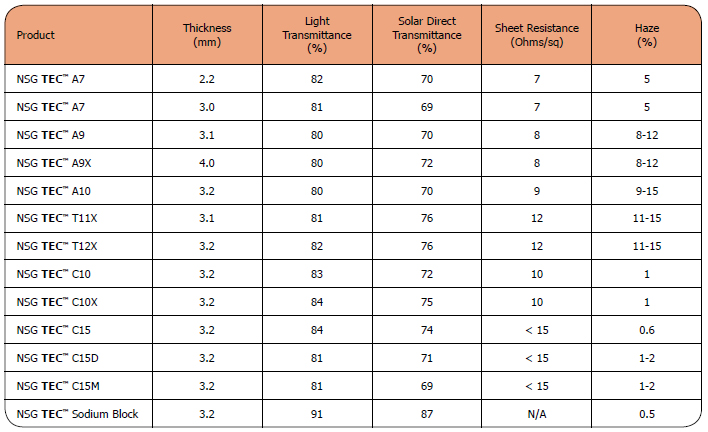

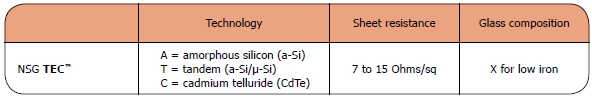

Each of our products within the NSG

TEC™ range is targeted at a particular thin film photovoltaic technology.

The NSG

TEC™ descriptive names indicate the technology to which the products are most suited as well as the corresponding technical values.

Higher haze values are desirable for thin film silicon technologies which benefit from the light trapping effect from light scattering TCO glass. Alternatively, other thin film photovoltaics like CdTe, offer good light absorption and do not benefit from a light scattering TCO glass. A smooth TCO glass with a low haze value will be required for those thin film technologies. All of our NSG

TEC™ products includes a sodium barrier layer which gives the product stability throughout the thin film photovoltaics manufacturing process and throughout the lifetime of the solar module.

NSG TEC™ Sodium Block is used for CIS/CIGS applications. It includes a sodium barrier layer, which offers manufacturers improved product stability and increased process throughput. Low iron NSG TEC™ Sodium Block is used as substrate for solar mirrors in concentrated solar power applications. The sodium barrier layer offers improved product shelf-life and durability and can offer solar mirror manufacturers improved stability.

The properties of our main NSG TEC™ products are summarised in the table below: