Today we'll look at why axle geometry is crucial for Advanced Driver Assistance Systems (ADAS).

For any electrical system to work effectively and without failure, the mechanical system must be in good working order.

If we look at the calibration of a camera and radar system, it means, the control units need an intact chassis as a base. If this works, then you're already one step closer to successful calibration.

So, how does this affect you as a fitter?

Vehicles with ADAS should always be given a test drive first. This allows you to quickly spot any major flaws in the axle geometry. The test drive is part of the initial diagnosis and is absolutely essential. Here are two important things you should pay attention to during a test drive.

1. Steering behaviour

Does the vehicle drive straight ahead without correction, or do you have to give an above-average amount of assistance?

A possible cause for this could be tires worn on one side and a misaligned track of the vehicle. A defective wishbone bearing is also likely culprit.

2. Acceleration and braking behaviour

Does the vehicle pull to one side when accelerating or braking? This can be caused by one or more defective wishbone bearings. Other possible causes are defective tie-rods or tie-rod ends.

If a faulty axle geometry could be the problem, the best way to get a good overview of the situation is to get the car on the platform and to carry out a measurement of the axle geometry. No lifting platform available? Then why not arrange a partnership with an adjacent car workshop.

But why does axle geometry play such an important role? Here's a brief explanation.

Up to 80 percent of the directional stability of a vehicle is maintained by the rear axle. If the front axle was not used to steer the vehicle, the vehicle would follow the direction of the rear axle ("thrust angle"). So, the vehicle would tend to head in a certain direction, e. g. to the left-hand side. But since the driver wants to go straight, he steers against this tendency.

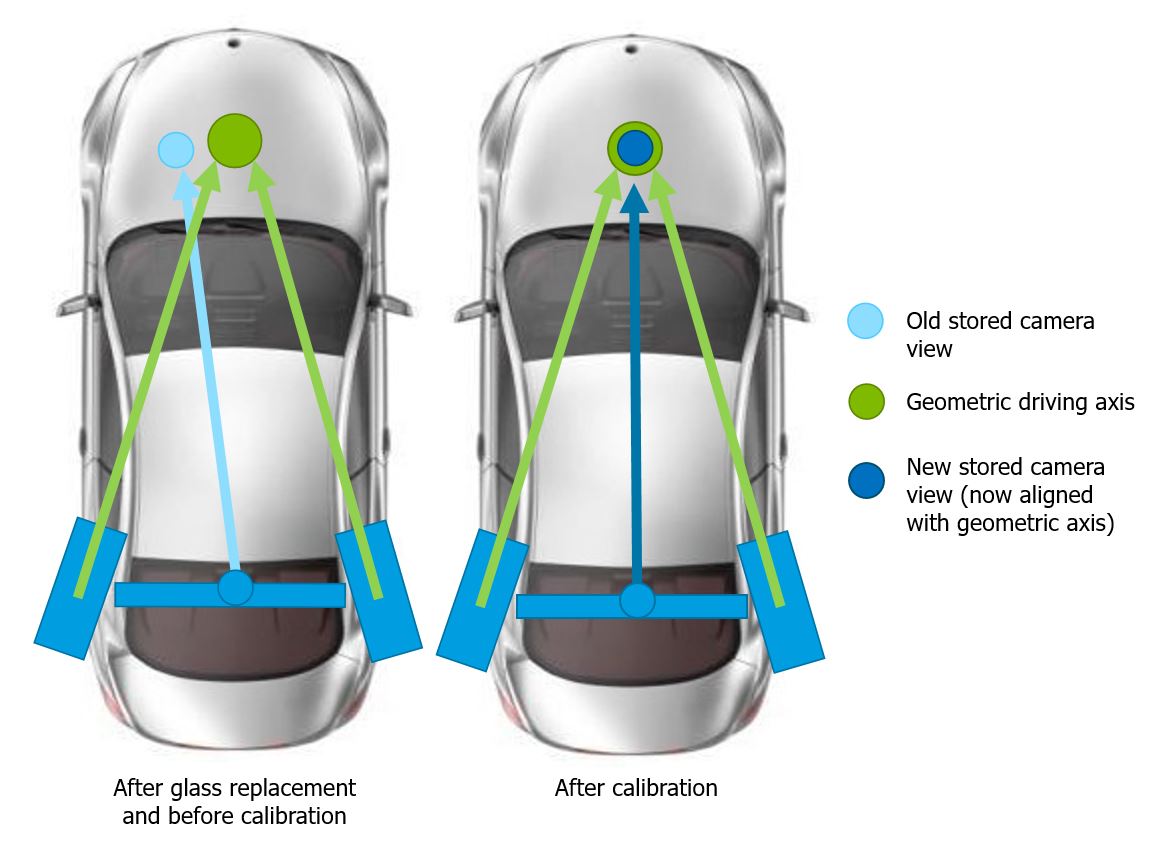

Geometric driving axis

The geometric driving axis is formed by the position of the rear wheels. When driving straight ahead, the car body is aligned along the geometric driving axis.

The ADAS camera view tends to follow the axis of symmetry in general, but depends on the mounting position and positioning of the windscreen and camera and can therefore deviate slightly from the axis of symmetry. The axis of symmetry is the centre line of a car body. The perspective and viewpoint of the camera is independent of the geometrical driving axis.

Calibration corrects for the difference between viewpoint of the camera and geometric axis. This is a crucial step to allow the ADAS camera to work properly.

Therefore, the calibration target is aligned parallel with the geometric driving axis. By doing this, the camera saves a new reference point which tells the camera "This is where you have to face when driving straight ahead". The whole process can also be used for radar systems directed to the front.

Some calibration systems align the target solely along the axis of symmetry for the camera. This is reasonable, however, the procedure described above is always the better and more accurate method. At the very least, when radar systems are used, alignment along the geometric axis of travel is a must.

Like other parts of the vehicle, the chassis is also very complex: from McPherson strut to multilink suspensions and adaptive chassis control - modern vehicles feature a variety of options. For you, as a fitter, it’s important to ensure that the chassis is in a technically perfect condition during calibration. If there's any doubt, it may be a good idea to carry out an initial measurement or have it carried out by a specialist company. Calibration systems of well-known manufacturers are available, which offer different ways to inspect the axle geometry prior to calibration.